In a groundbreaking move that highlights Apple’s commitment to innovation and sustainability, the tech giant has announced the use of 3D printing technology to produce its latest Apple Watch models, specifically the Apple Watch Ultra 3 and the titanium Apple Watch Series 11. This marks a significant milestone in manufacturing as Apple shifts from traditional methods to a more environmentally friendly and efficient process.

The concept of using 3D printing for mass production, especially with high-quality recycled materials, is not new. However, what sets Apple’s approach apart is the scale and precision they have achieved. Kate Bergeron, Apple’s Vice President of Product Design, emphasized that the idea quickly transitioned from concept to reality through rigorous testing and prototyping. The objective was to ensure that the technology could meet Apple’s high standards for quality and design.

Apple’s commitment to sustainability is evident in its ambitious Apple 2030 initiative, which aims to achieve carbon neutrality across its entire operation by the end of this decade. The company’s focus on environmental responsibility is reflected in the use of 100% recycled aerospace-grade titanium powder for its 3D-printed watch cases. This material is not only durable and lightweight, ideal for everyday use, but it also aligns with Apple’s goal of reducing its carbon footprint.

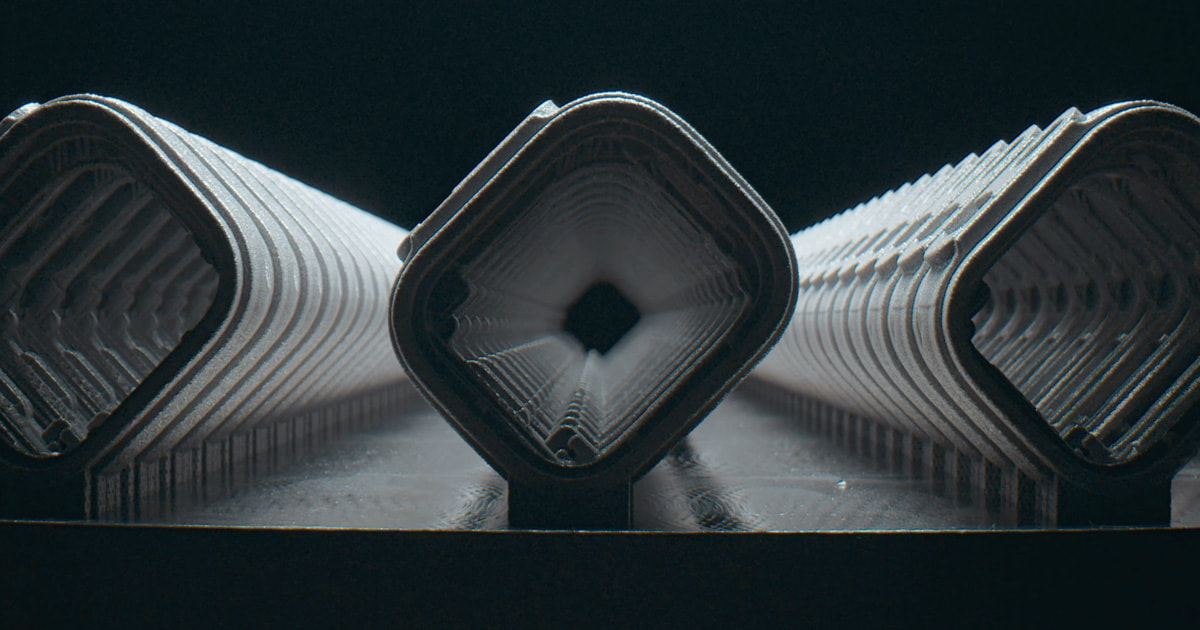

The 3D printing process itself is a marvel of modern engineering. Unlike traditional manufacturing methods that are subtractive, involving significant material waste, 3D printing is an additive process. This means that material is added layer by layer until the desired shape is achieved, significantly reducing waste. In the case of the Apple Watch, this means using only half the raw material compared to previous models, a massive reduction that Sarah Chandler, Apple’s Vice President of Environment and Supply Chain Innovation, describes as having a tremendous positive impact on the environment.

This year alone, Apple anticipates saving over 400 metric tons of raw titanium thanks to its innovative manufacturing approach. This achievement is a testament to the potential of 3D printing technology, which has evolved from creating simple prototypes to producing complex, high-quality components at scale.

Historically, 3D printing has been used in a variety of fields, from medical labs producing prosthetics to astronauts manufacturing tools in space. Apple has been exploring the potential of this technology for over a decade, gradually refining the process to meet its stringent design requirements. Dr. J Manjunathaiah, Apple’s Senior Director of Manufacturing Design for Apple Watch and Vision, highlights the company’s journey in experimenting with 3D-printed metal for cosmetic parts, which was previously considered unfeasible at scale.

The manufacturing process for these watch cases involves several advanced techniques. Each 3D printer at the facility is equipped with a galvanometer holding six lasers, working together to build the watch cases layer by layer. The raw titanium powder used in the process is meticulously atomized to ensure low oxygen content, which is crucial for the stability and quality of the material when exposed to heat.

Once the printing is complete, the cases undergo a process called rough depowdering, where excess powder is removed. This is followed by fine depowdering using an ultrasonic shaker to ensure no residual powder remains in the intricate designs of the cases. The precision required in this process is akin to finely squeegeeing the powder to achieve a consistent 60-micron thickness for each layer, balancing speed with precision to maintain scalability.

The intricacies of assembling the Apple Watch are described by Bergeron as a complex puzzle, requiring the integration of various components such as the circuit board, display, and battery into the compact case. Each watch is rigorously tested to ensure functionality before software is added to verify all operational requirements are met.

One notable design advancement made possible by 3D printing is the ability to create textures in previously inaccessible areas during traditional forging processes. This has allowed Apple to enhance the waterproofing of the antenna housing in cellular models, ensuring better bonding between the plastic and metal components.

The journey to perfect this process involved numerous prototypes and proof-of-concept tests. Apple’s success in overcoming the challenges associated with working with titanium has not only set a precedent for future product designs but also opened new avenues for design flexibility.

The impact of this innovation extends beyond the Apple Watch. The technology has also been applied to the development of the USB-C port on the new iPhone Air, which features a titanium enclosure crafted from the same recycled titanium powder. This achievement underscores Apple’s ability to create designs that are both thin and durable, showcasing the potential of 3D printing in revolutionizing product design.

In conclusion, Apple’s foray into 3D printing represents a significant step forward in sustainable manufacturing. By aligning cutting-edge technology with environmental responsibility, Apple continues to set new standards for the industry. This initiative not only demonstrates the company’s commitment to innovation without compromise but also highlights the potential for systemic change in manufacturing processes, ultimately benefiting both people and the planet.

For more information, readers can refer to the original announcement on Apple’s official newsroom website.

For more Information, Refer to this article.